Genesi is an advanced platform designed to create the Digital Twins of machines and plants, using real data, interactive physics, and integrated IoT technologies. Its evolution stands out for the synergistic integration of artificial intelligence, virtual/augmented reality, and motion tracking technologies in a single platform.

This approach makes simulation more accessible, intelligent and results-oriented, even for non-expert operators, while improving ergonomics, training and decision-making processes.

This project was carried out thanks to the support of the National Recovery and Resilience Plan (Piano Nazionale di Ripresa e Resilienza – PNRR) – Mission 4 “Education and Research” – Component 2 “From Research to Business” – Investment 2.3.

The initiative is funded by the European Union – Next Generation EU and aims to support the digitalization of local SMEs and promote a digital transition.

Project Objectives

What is Genesi and why is it revolutionizing the way systems are designed and managed?

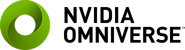

Designed for engineers, system integrators, and operators, Genesi enables the complete virtualization of machines and plants, integrating IoT technologies, 3D cinematic models, interactive physics, and haptic devices.

This makes design, training, and monitoring more efficient, secure, and sustainable.

The platform allows processes and solutions to be tested and optimized in a realistic virtual environment, thus reducing costs, time, and environmental impact before actual implementation.

Genesi is based on the open source Unreal Engine platform developed to create interactive and photorealistic 3D environments in real time.

Real data, interactive simulations, remote control

Genesi gets real-time data from PLCs, sensors, and HMIs through IoT connections, syncing it with an interactive 3D model that accurately replicates the behavior of the machine or plant.

The platform supports bidirectional data flow, allowing not only to monitor but also to interact remotely with the systems.

Through the MIS (Machine Interaction Simulation) module and the integration of haptic gloves, it is possible to simulate real operations in safe and immersive virtual environments.

Genesi is compatible with standard industrial protocols and can be integrated with SCADA and MES systems, ensuring interoperability and scalability in complex industrial contexts.

Main Benefits

Reduced design and testing times

Immersive and safe training for operators

Integration with real production environments

Advanced visualization of machine statuses and alarms

Failure prevention through predictive simulation

Training on machines or entire plants

Digital Twin allows to create a realistic virtual replica of machines or entire plants, where operators can practice in complete safety.

Thanks to an improved user interface and the integration of haptic gloves and motion tracking systems, the platform allows users to study the ergonomics of movements and refine their operational skills in an immersive and controlled environment.

This approach accelerates learning, improves safety, and reduces training time by giving operators hands-on experience in realistic scenarios before their actual intervention.

Computer vision & autonomous learning

The evolution of Genesi's framework aims to integrate artificial intelligence and computer vision technologies to make the platform more autonomous and predictive.

The goal is to enable the system to analyze data and images from virtual models in order to recognize components, monitor operating conditions, and identify any anomalies.

These features will help optimize simulation and maintenance processes, providing engineers and operators with intelligent support that improves efficiency, reduces intervention times, and prevents operational critical issues.

Virtual assistent - AI Ready

The integrated Virtual Assistant uses artificial intelligence to provide immediate operational support during simulation and training activities.

It is able to understand user requests, report errors, suggest solutions, and provide step-by-step guidance through procedures.

Its AI-Ready nature allows it to continuously evolve, while learning from data and adapting to different application contexts, in order to make interaction more fluid, reduce response times, and increase the platform’s overall efficiency.

Product features

Native support for 3D CAD models

Real-time connection with PLC

Real-time connection with robot controller

Real-time HMI machine integration

Kinesim: Integrated virtual soft PLC

TCP-IP, OPC UA, MQTT, Modbus, and ROS 2 compatibility

Additional specifications

Cinematic simulator with real-time physics

Integration with haptic devices

Integrated training procedure creation system

Customizable monitoring dashboards

Scripting engine for custom logic

Setup for ML and RL

Get the brochure

Find out all about how Genesi is changing the game in industrial simulation, support, and training.

News and updates

Stay up to date with the latest innovations

Partnership

WEART provides haptic solutions that replicate realistic tactile sensations in digital and Extended Reality experiences.

TraceParts is one of the world's leading CAD content platforms for the engineering, industrial equipment, and machine design sectors. The platform has 5.8 million registered users from 1.3 million companies who actively search for and find product information and technical data from over 195 different countries.

Connected external systems

Genesi connects natively with platforms such as NVIDIA Omniverse for collaboration and real-time AI-based models, ANSYS SpaceClaim for multi-physics simulation, and Algorix for the integration of advanced physical models into digital twins.

Need more info about Genesi?

Find out how the platform can optimize the design, safety, and efficiency of your facilities, while supporting operators and business processes.

Genesi is Applied's proprietary platform for industrial simulation and Digital Twins.

Developed in-house, it integrates automation, IoT, and real-time 3D skills to offer companies a comprehensive and customizable solution, backed by Applied's experience and direct support.

Funded by the European Union – Next Generation EU.

The views and opinions expressed are those of the authors alone and do not necessarily reflect those of the European Union or the European Commission. Neither the European Union nor the European Commission can be held responsible for them.